Authors:

Hamied Nabizada、Tom Jeleniewski、Felix Gehlhoff、Alexander Fay

Paper:

https://arxiv.org/abs/2408.08145

Introduction

The rapid advancement of technology has led to increasingly complex production systems and products. Model-Based Systems Engineering (MBSE) has emerged as a powerful approach to address these challenges by providing a structured methodology for modeling, analyzing, and managing complex systems. MBSE promotes the use of models to provide detailed and consistent descriptions of production systems, facilitating efficient collaboration among various disciplines involved in the development process.

However, MBSE methods often require numerous manual steps, such as assigning individual process steps to potential technical resources, which demands a high level of expert knowledge. This is particularly true when comparing different system variants to determine the ideal configuration for specific optimization goals. Automating this process planning is desirable to reduce the time required to evaluate different system variants. This paper presents a comprehensive workflow for the automated generation of Planning Domain Definition Language (PDDL) descriptions from system and product models, leveraging MBSE to enhance the planning process.

Related Work

Several approaches have been proposed to generate PDDL descriptions:

- Huckaby et al. introduced a SysML taxonomy for assembly tasks to describe system capabilities, forming the basis for deriving PDDL actions. However, the PDDL descriptions are created manually and are limited to the taxonomy.

- Vieira da Silva et al. presented an ontology-based approach to automatically generate PDDL descriptions by matching required and offered capabilities. This approach requires a specific capability model and does not use existing models.

- Rimani et al. simplified planning problems in Hierarchical Domain Definition Language (HDDL) by comparing HDDL and SysML elements and proposing a conceptual workflow for modeling HDDL. However, the transformation must be done manually.

- Wally et al. described an approach that converts ISA-95 manufacturing system models into PDDL descriptions for production planning. This approach is limited to ISA-95 systems and does not integrate with other models.

- Konidaris et al. presented a method for developing abstract symbolic representations to aid high-level planning in robotics, focusing on how robots can utilize these representations derived from sensorimotor data.

- Stoev et al. presented a tool for automating the generation of domain-specific symbolic models from texts, streamlining the process by extracting domain knowledge from instructional texts and automatically generating PDDL descriptions.

- Nabizada et al. introduced a dedicated SysML profile that embeds PDDL constructs directly into SysML models, facilitating automated planning by creating an interface between system modeling and planning algorithms.

While these approaches contribute valuable methods for generating PDDL descriptions, they often require manual intervention, lack integration with existing models, or are limited to specific frameworks. Therefore, there is a need for a comprehensive workflow that leverages existing system and product models, integrating them seamlessly to generate automatically PDDL descriptions.

Workflow for Automated Generation of PDDL Descriptions

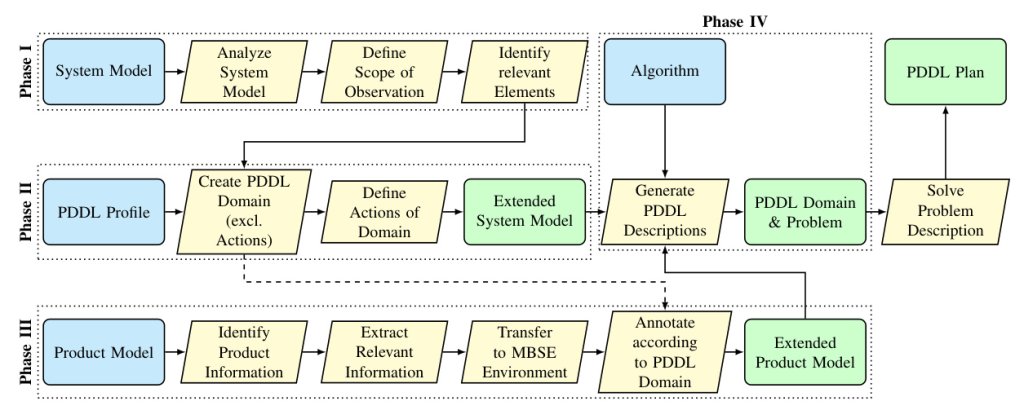

The proposed workflow model facilitates the automated generation of PDDL descriptions by systematically analyzing and enriching existing system and product models. It consists of four phases: Analysis and Preparation of the System Model, Enrichment of the System Model, Provision of the Product Model, and Generation of PDDL Descriptions. The entire workflow is depicted in Fig. 1 and is explained in detail below.

Phase I: Analysis and Preparation of the System Model

The workflow requires a system model as a starting point, typically modeled using SysML. A system model offers a comprehensive representation of a system encompassing structural, behavioral, functional, and operational information, as well as constraints, requirements, and quality attributes. The use of SysML is a prerequisite for the proposed workflow, as it allows for a structured and consistent representation of the system components and their interactions.

- Analyze System Model: Analyze and understand the existing system model to ensure all relevant components and relations are recognized.

- Define Scope of Observation: Define which parts of the system model will be the scope of observation to avoid unnecessary complexity.

- Identify Relevant Elements: Identify which elements within the system model’s scope are relevant for the current planning problem.

Phase II: Enrichment of the System Model

In Phase II, the goal is to enrich the system model with planning-specific aspects using the SysML Profile for PDDL.

- Create PDDL Domain (excl. Actions): Define the static parts of the domain, including objects, predicates, and types that represent the system’s components and their properties.

- Define Actions of Domain: Define actions that can be performed within the system, including preconditions and effects.

Phase III: Provision of the Product Model

The product model supplies essential information for defining the PDDL problem, describing the specific instance of the planning task.

- Identify Product Information: Identify relevant product information from the existing product model.

- Extract Relevant Information: Extract this information from the product model.

- Transfer to MBSE Environment: Transfer the extracted product information to the MBSE environment.

- Annotate according to PDDL Domain: Annotate the product information according to the PDDL domain.

Phase IV: Generation of PDDL Descriptions

In Phase IV, the focus is on automatically generating a problem description that can be submitted to a solver to create a feasible plan.

- Generate PDDL Descriptions: Generate PDDL descriptions, including both the PDDL domain and the PDDL problem file.

- Solve Problem Description: Submit the generated PDDL files to a PDDL solver to solve the planning problem.

Application Example

To validate the developed workflow, a use case from aircraft structure assembly was utilized, featuring a UR10 robotic arm within the fuselage for screwing collars onto rivets, each requiring specific end-effectors. The workflow leveraged existing system and product models, developed in Magic Systems of Systems Architect (MSoSA) and 3DExperience respectively, to optimize process flow and reduce throughput times.

The process involved extracting rivet information from the 3D product model, which was necessary to define the PDDL problem description. For the generation of the PDDL files, Velocity Template Language (VTL) templates were utilized. These templates structure the output of planning information into the standardized PDDL format. By using placeholders dynamically filled by the Velocity Engine integrated within MSoSA, VTL templates systematically transform domain-specific data extracted from system and product models into valid PDDL files.

The application of this workflow successfully demonstrated the capability to generate correct PDDL descriptions from the system and product models and solve them by a PDDL solver. The resulting plan was compared against the expected assembly process to ensure correctness. Actions generated by the solver were checked for logical consistency and alignment with the system and product specifications.

Conclusion and Future Work

This contribution outlines a model-based workflow for generating PDDL descriptions that integrates system and product models. This workflow consists of four phases, detailing the steps required to enhance existing system and product models, and automate the generation of PDDL files. Integrating this approach facilitates efficient and flexible planning processes, improving decision-making in complex systems engineering by providing a robust plan that supports engineering decisions and adapts to changes in the models.

To validate the workflow, a use case from aircraft structure assembly was utilized. Unlike the approach by Wally et al., which is limited to ISA-95 systems and does not integrate with other models, this workflow is designed to be flexible and applicable across various modeling standards. This flexibility allows for the integration of different system and product models, making it more adaptable to diverse industrial applications.

However, the workflow faces challenges due to the heterogeneity of models, since modeling standards vary significantly among modelers. Standardizing the MBSE modeling workflow could automate these currently manual steps. Future work will focus on further refining this workflow and applying it to more complex systems to ensure its applicability in industrial use cases. Additionally, the underlying algorithm will be thoroughly documented and published, providing detailed insights into its functionality and implementation.

This will enable broader application of the workflow across various tools beyond MSoSA, facilitating its use in a wide range of engineering and planning contexts.