Authors:

Duong Nguyen、Ana Ulianovici、Sami Achour、Soline Aubry、Nicolas Chesneau

Paper:

https://arxiv.org/abs/2408.08637

Magazine Supply Optimization: A Case Study

Introduction

The print magazine industry has faced significant challenges due to the rise of digital media. This shift has led to a decline in print magazine sales, making it difficult for publishers to maintain profitability and relevance. Additionally, the industry is under pressure to adopt sustainable practices due to environmental concerns and rising production costs. Efficient supply optimization is crucial in this context to minimize losses from out-of-stock situations and reduce the costs associated with excess supply.

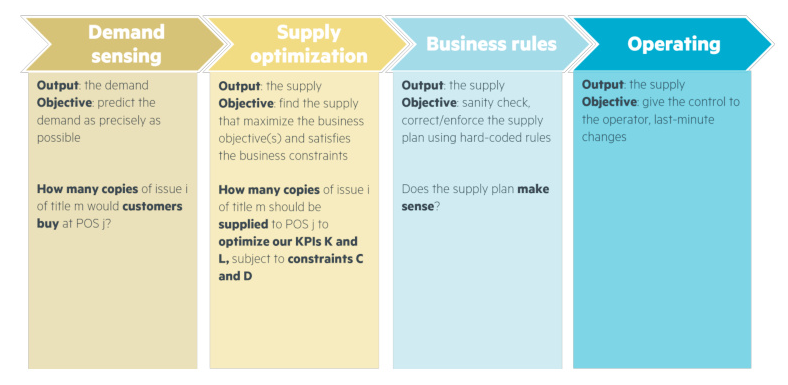

However, optimizing magazine supply is complex due to the fixed inventory nature of the industry, irregular sales patterns, and varying characteristics of products and points of sale (POS). This paper introduces AthenIA, a magazine supply optimization solution designed to address these challenges. AthenIA modularizes the supply planning process into four stages: demand sensing, optimization, business rules, and operating. The core of the solution is a novel group conformalized quantile regression method that integrates domain expert insights and a supply optimization technique that balances the costs of out-of-stock against the costs of over-supply.

Problem Formulation

The objective of the solution is to optimize profit under constraints. Mathematically, the problem can be formulated as follows:

[ \max_{s_{j}^{m,i}} \sum_{j \in P_{m,i}} \left( z_{j}^{m,i} \cdot \text{price}{m,i} – \text{cost}{j}^{m,i}(s_{j}^{m,i}, s_{m,i}, z_{j}^{m,i}) \right) ]

Subject to:

[ s_{j}^{m,i}, z_{j}^{m,i} \in \mathbb{Z}{0+}, ]

[ s{m,i} \in [N_{\text{total}} – \Delta, N_{\text{total}} + \Delta] ]

Where:

– ( P_{m,i} ) denotes the plate of issue ( i ) of title ( m ).

– ( s_{j}^{m,i} ) denotes the supply of issue ( i ) of title ( m ) for POS ( j ).

– ( s_{m,i} ) denotes the total supply of issue ( i ) of title ( m ).

– ( N_{\text{total}} ) denotes the total supply constraint.

– ( \Delta ) denotes the tolerance of the total supply constraint.

– ( z_{j}^{m,i} ) denotes the sales of issue ( i ) of title ( m ) at POS ( j ).

– ( \text{price}{m,i} ) denotes the price of issue ( i ) of title ( m ).

– ( \text{cost}{j}^{m,i} ) denotes the costs and commission taken by POS ( j ).

The challenge lies in estimating the demand (( d_{j}^{m,i} )) and optimizing the supply (( s_{j}^{m,i} )) to maximize profit while adhering to constraints.

AthenIA Supply Optimization Solution

Pipeline

The supply optimization process is modularized into four stages:

- Demand Sensing: Estimate the demand for each issue at each POS.

- Optimization: Calculate the optimal supply based on the estimated demand, considering different costs, constraints, and strategies.

- Business Rules: Apply predefined rules to sanity-check the proposed supply plans and make ad-hoc adjustments.

- Operating: Generate several optimal supply plans, allowing the supply planner to select the most appropriate plan and make necessary manual adjustments.

Human-in-the-loop Demand Sensing Using Group Conformalized Quantile Regression

The demand for an issue at a POS depends on various factors, including the quality and popularity of the title, extra-products, market trends, and POS characteristics. To address the complexities, the following simplifications are made:

– If the supply exceeds the sales, the demand is considered equal to the sales.

– The demand does not depend on the supply.

A demand sensing model is built using historical demands, product characteristics, sales characteristics, and contextual information. LightGBM is used for the demand sensing model due to its ability to handle irregular selling periods and varying issue durations.

Group Conformalized Quantile Regression (GCQR) is introduced to improve the performance of standard quantile regression by calibrating the outputs using a calibration set. This approach provides more accurate and narrower prediction intervals, reducing the risk of oversupply.

Supply Optimization

The demand sensing model provides the prediction of the ( \alpha )-th quantile of the demand. The supply optimization process involves:

1. Estimating several quantiles corresponding to different values of ( \alpha ).

2. Constructing several scenarios, each represented by a vector of ( \alpha ) values for different groups.

3. Calculating business KPIs (total supply, revenue, costs, and profit) for each scenario.

4. Selecting a set of optimal scenarios based on predefined criteria.

5. Generating three supply plans: optimal supply plan, optimal distribution plan, and a plan for widening the presence of the magazine.

Business Rules and Operating

Rule-based checks and adjustments are applied to control the outputs of the optimization stage. These rules ensure that the proposed supply plans are practical and aligned with current market conditions and constraints. The final supply plan is reviewed and adjusted by supply planners before being sent to the production and shipping departments.

Evaluation

Evaluation of the Demand Sensing Model

The performance of the demand sensing model is evaluated using a dataset containing sales records from 01/01/2021 to 31/05/2023. The model is compared with several baselines and alternative options, including Naive, S-Naive, and different LightGBM models. The results show that the LightGBM log GCQR model achieves the best quantile scores, supporting its choice for the solution.

Evaluation of the Supply Optimization Method

The performance of different supply plans is compared using the same dataset. The optimal distribution plan and optimal supply plan yield better profits and fewer out-of-stock instances compared to the real supply plan and a quantile regression-based plan. This indicates that the demand estimations are more accurate, and the supply optimization method effectively balances the costs of out-of-stock and oversupply.

Deployment

AthenIA is a fully industrialized solution hosted in an Azure Data Lake and executed on a Databricks cloud platform. MLOps practices are applied to ensure a robust and scalable lifecycle. A web application allows users to input product information, select and download supply plans, and visualize statistics. Quarterly meetings with business stakeholders review the performance and effectiveness of the strategies and models.

Related Work

Previous studies on magazine supply optimization have primarily focused on demand estimation. AthenIA stands out as an end-to-end industrialized supply optimization solution operating at a large scale. The demand sensing model leverages machine learning techniques and domain expert insights, while the supply optimization method accommodates complex cost structures and business strategies.

Conclusion

AthenIA addresses the challenges of magazine supply optimization by integrating advanced machine learning techniques with practical business insights. The solution has proven to be valuable for magazine publishers, helping to reduce the carbon footprint associated with over-supply and paving the way for a more sustainable operational model. Future work may involve assessing the impact of demand-supply dependence and incorporating carbon costs into the optimization equations.