Authors:

Jan Lewen、Max Pargmann、Mehdi Cherti、Jenia Jitsev、Robert Pitz-Paal、Daniel Maldonado Quinto

Paper:

https://arxiv.org/abs/2408.10802

Introduction

Concentrating Solar Power (CSP) plants are pivotal in the transition to sustainable energy. A critical aspect of CSP plant efficiency is the distribution of concentrated flux density on the receiver. However, non-ideal flux density from individual heliostats can compromise plant safety and efficiency. The flux density is influenced by the heliostat’s surface profile, including canting and mirror errors. Measuring these profiles accurately for numerous heliostats is challenging, leading to reliance on ideal surface conditions, which is suboptimal.

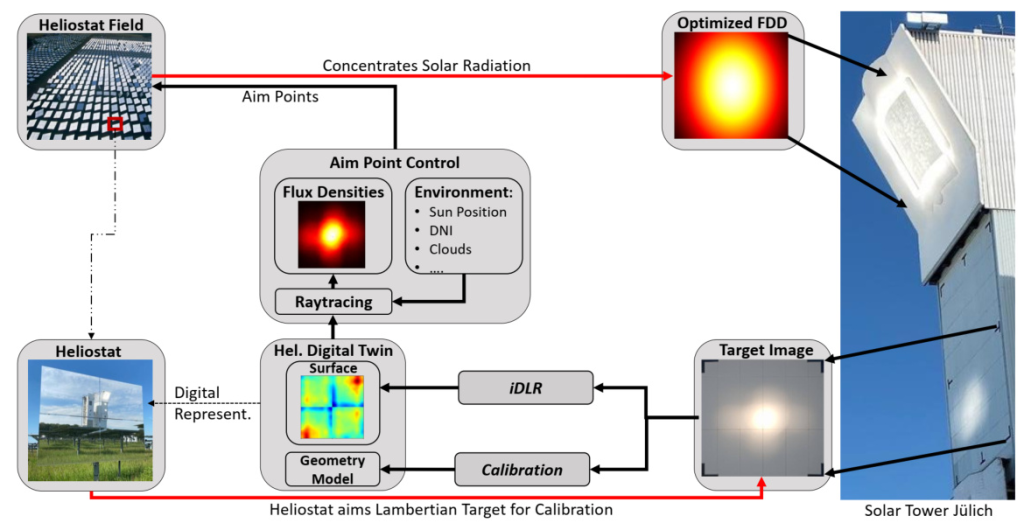

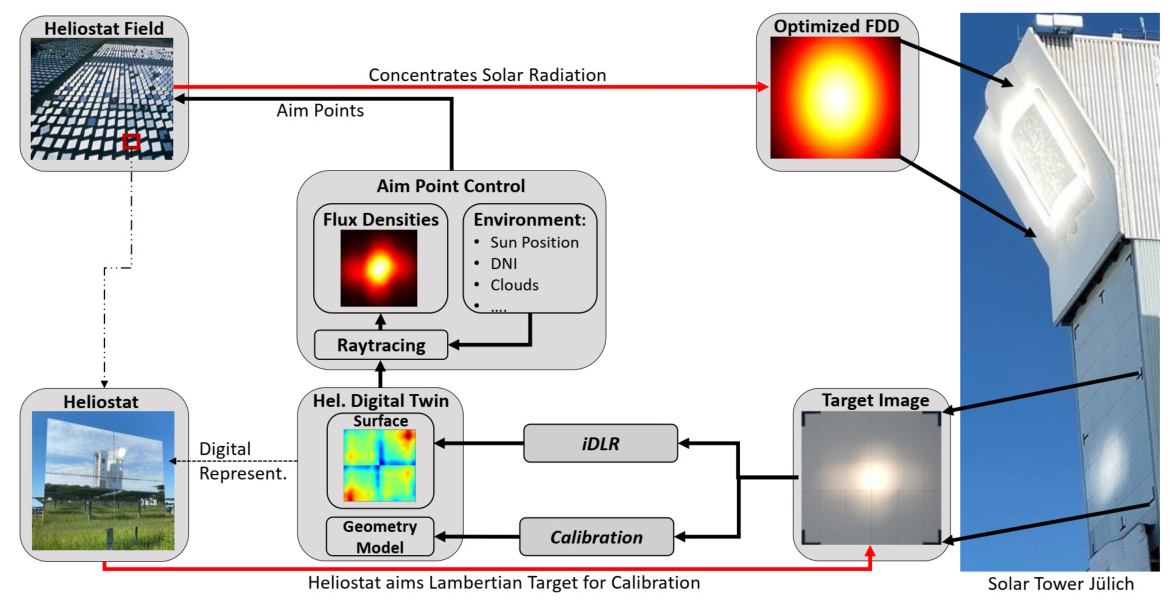

This study introduces inverse Deep Learning Ray Tracing (iDLR), a novel method to predict heliostat surfaces using target images obtained during calibration. The simulation-based investigation shows that deep learning models can predict heliostat surfaces with high precision, enhancing CSP plant operations and potentially increasing efficiency and energy output.

Related Work

Existing Methods for Flux Density Optimization

Optimizing flux density distribution on the receiver is crucial for CSP plant efficiency. Traditional methods include:

– Ant-colony optimization meta-heuristic [1, 2]

– Deep learning models [3]

– Vant Hull algorithm [5, 6]

These methods rely on ray tracing to calculate flux density and optimize distribution. However, they often assume ideal heliostat surfaces, which is not always accurate.

Heliostat Surface Measurement Techniques

Current state-of-the-art methods for measuring heliostat surfaces include:

– Deflectometric measurement [11, 12]

– Laser scanning [13, 14]

– Photogrammetry [15, 16, 17, 18, 19]

– Flux mapping [20]

These methods face challenges such as environmental conditions, cost, and reliability. Zhu et al. [4] developed a calibration procedure using target images, but it has limitations in predicting complex surface features.

Differentiable Ray Tracing

Pargmann et al. [21, 22] proposed a versatile approach using differentiable ray tracing for heliostat calibration and surface reconstruction. However, this method struggles with the underdetermined nature of the problem.

Generative Deep Learning Models

Generative models like StyleGAN [23], Large Language Models [24], and Diffusion Models [25] have shown promise in various domains. These models can predict outcomes even in underdetermined regimes, making them suitable for heliostat surface prediction.

Research Methodology

Workflow of Inverse Deep Learning Ray Tracing

The iDLR method uses deep learning models to predict heliostat surfaces from target images, reversing the direction of physical ray tracing. The workflow integrates iDLR into routine power plant operations, leveraging deep learning to extract surface information from target images without additional hardware or manual measurements.

Comprehensive NURBS Heliostat Model

The study employs a heliostat model using Non-Uniform Rational B-Spline (NURBS) for surface parameterization. This model reduces the number of parameters significantly, enhancing computational efficiency and precision.

Data Acquisition and Augmentation

The dataset includes deflectometry measurements from the Solar Tower Jülich (STJ), with data augmentation techniques applied to generate a diverse training set. The model is trained on a semi-artificial dataset, combining real surface measurements and simulated flux density data.

Experimental Design

Model and Training

The model uses an Encoder-Decoder architecture with the StyleGAN2 generator. The encoder processes flux densities and scalar data (sun and heliostat positions), while the decoder generates the surface spline. The model is trained on the semi-artificial dataset for 50 epochs.

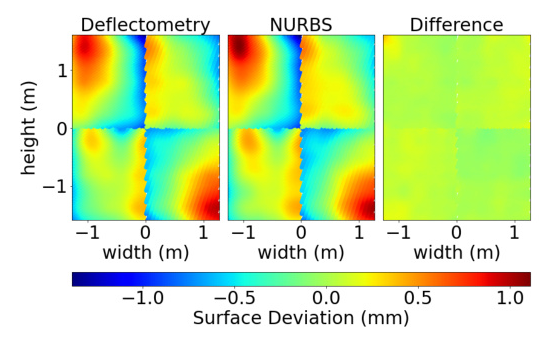

Quality and Computational Efficiency of NURBS

The NURBS parameterization is compared to deflectometry normal vector point clouds, showing minimal differences and high accuracy. The parameter reduction enhances memory and computational efficiency, crucial for large CSP plants.

Results and Analysis

Surface Prediction

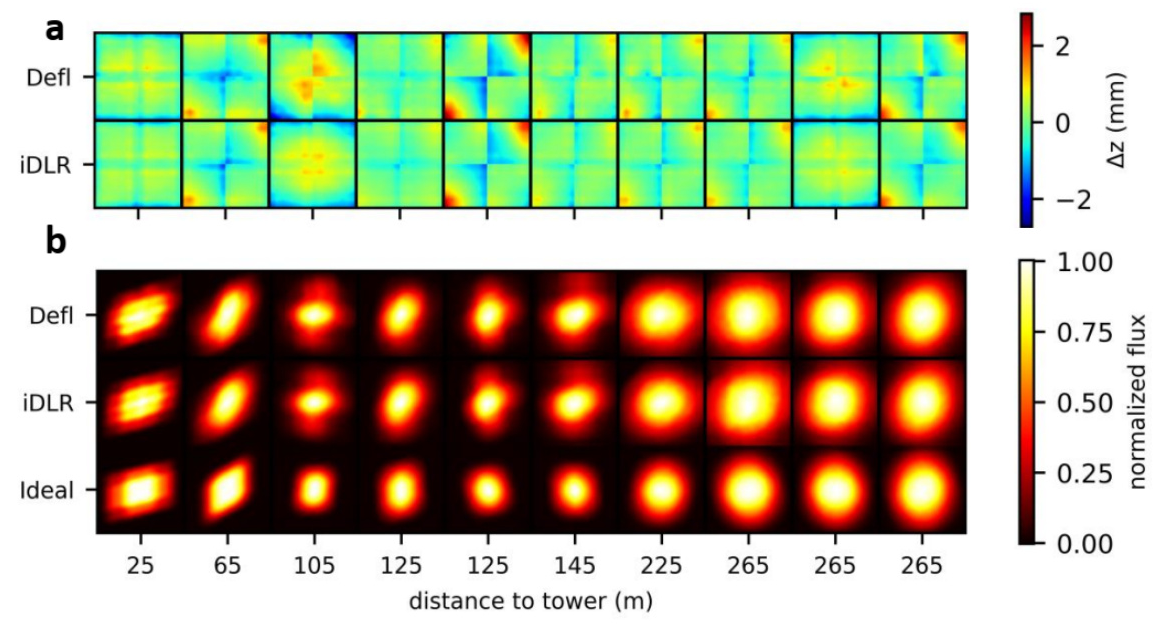

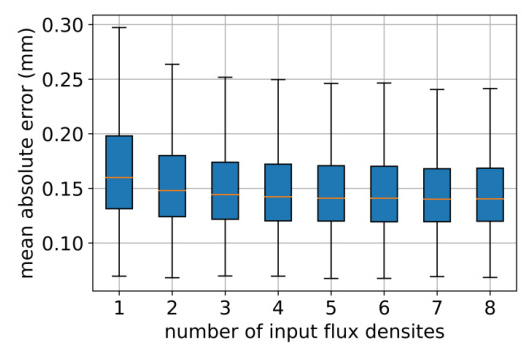

The iDLR model predicts heliostat surfaces with a median Mean Absolute Error (MAE) of 0.14 mm. The predictions align well with deflectometry ground truth surfaces, accurately capturing high-frequency surface features.

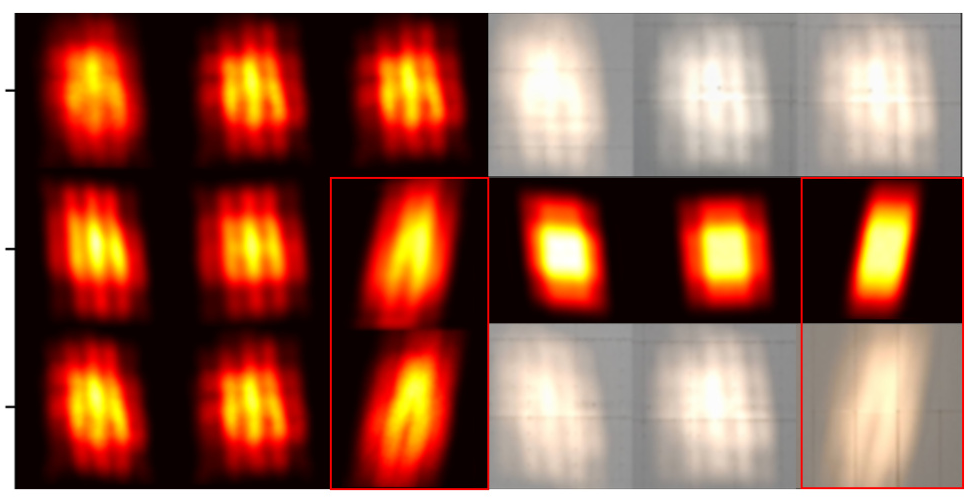

Flux Density Prediction

The predicted surfaces are used to forecast flux densities using ray tracing. The iDLR predictions significantly outperform the ideal heliostat assumption, with a median accuracy of 0.92 compared to 0.67 for the ideal assumption.

Spatial Extrapolation

The model successfully predicts flux densities for different target planes, demonstrating its capability for spatial extrapolation, crucial for real-world applications.

Overall Conclusion

The iDLR method shows significant potential for predicting heliostat surfaces from target images, enhancing CSP plant efficiency. The predicted surfaces are accurate and cost-effective, making iDLR a promising approach for real-time heliostat surface prediction and flux density optimization.

The study highlights the importance of integrating advanced deep learning techniques into CSP plant operations, paving the way for more efficient and sustainable energy production.

Competing Interests: The authors declare no competing interests.

Acknowledgements: The authors acknowledge the use of data from the Solar Tower Jülich and funding from the Helmholtz Association (HGF) for the GANCSTR project.